Stock containment areas

This guide to stock containment areas will help you to understand the benefits of using stock containment areas, as well as how to plan and construct a containment area to best suit your property and needs.

It is important to remember that stock placed in containment areas are 100% reliant on the operator for nutritional requirements, water and management.

What are stock containment areas?

Stock containment areas are fenced areas where livestock is temporarily held, fed and watered to protect soil and pasture resources on a property. They are valuable ways to keep stock healthy and in good condition during drought or emergencies by temporarily enabling the maintenance feeding of livestock at high stocking rates.

Stock containment areas are sometimes referred to as ‘drought lots', and should be constructed as part of your general on-farm drought management plan.

Stock containment areas are much more than simply an area of your farm that you use during a drought. They can be a versatile management tool that should be considered as part of your overall livestock management strategy.

Benefits of using stock containment areas

There are a range of benefits these facilities offer, including:

- ready access for feeding, watering, monitoring and handling stock

- containment of weeds brought on to the property with imported feed

- control of livestock when large areas of the farm require fencing (i.e. following a fire or other emergency)

- enabling faster pasture establishment or recovery after drought or fire, or just in challenging seasons

- reduced soil erosion or damage to paddocks during a drought or dry conditions

- providing quarantine areas for introduced stock

- pasture maintenance or improvement due to the ability to rest paddocks and allow pasture to recover

- improvement or maintenance of stock condition – can help to reduce feed and energy wastage, and help to meet weight targets to assist in joining

- close monitoring and management of animal health

- better use of labour and feeding resources (less time spent feeding, and better management of stock nutrition)

- more efficient way of supplying quality water to stock.

Establishing a stock containment area

There are standard stock containment area requirements that apply regardless of whether you are setting up for containment feeding during drought, for easier animal handling and monitoring, as a quarantine area for new stock, for pasture maintenance, or in response to an emergency situation. However, specific pen design may vary according to need.

At a minimum when setting up an SCA you need:

- a suitable site considering slope and drainage

- minimum area per stock class

- separation of stock classes

- reliable fencing

- separate water and feed areas

- stabilised soil around troughs

- a reliable water supply

- shelter and shade

- vehicle access.

Confinement feeding area site selection

Selecting a suitable site for a stock containment area or confinement feeding area for sheep or cattle can be challenging. Consideration needs to be given to a range of requirements, while the integration of a confinement feeding area into the overall property layout and plan is crucial.

Time spent investigating location options and selecting the most appropriate site for both intensive stock management areas and confinement feeding is time well spent and likely to minimise long term issues. Unfortunately, you are unlikely to have a site that meets all requirements or needs. Ultimately, most sites will have some degree of compromise.

The objective is to select a well-drained, sheltered site; close to feed storage, water supply and stock handling facilities, while minimising any negative environmental or amenity impacts.

There are several criteria that need to be considered, both for dry and wet conditions, when selecting the best site. While the area may be primarily used as a confinement feeding area during dry conditions or following drought while pastures recover enough to produce sufficient quantity of feed, it should also be able to function during emergencies such as bushfire and flood, or as a stock management area for quarantine.

Buffer or separation distances

The stock containment feeding area needs to be located to ensure run-off does not cause contamination of any natural watercourses, water storages or neighbouring properties. The impact of odour, dust, noise, insects and visual amenity on neighbours or the community also needs to be considered.

Buffer or separation distance is the distance between the stock confinement area and the listed receptor, to minimise the risk of contamination or impact. The minimum recommended buffer distances are:

- major watercourse 200 metres

- ‘other’ watercourse 100 metres

- property boundary 20 metres

- neighbouring dwelling 500 metres

- public road 200 metres.

Stock confinement areas should be located above the 1-in-100-year average recurrence interval flood height. If you are concerned about flooding please contact your local council.

Topography

A sites topography will influence run-off drainage, potential for erosion and can impact animal health.

The selected site should have some slope to assist with run-off, avoid ponding and reduce the development of boggy conditions. A slope of between 2-4% is ideal for confinement pens. Steep slopes (>4%) can be prone to erosion and increase stock feed requirements.

For either pens or small paddocks it is important to avoid flat areas or drainage lines, low in the landscape, that are likely to accumulate water. Sites near the top of the slope are preferred, as they limit run-off water entering the area from above and generally provide good drainage. Levy banks can also be used to divert run-off around a potential site.

During periods of wet weather, a poorly drained site will become wet and boggy which:

- predisposes stock to health issues and diseases like foot abscess, scald, coccidiosis and salmonellosis

- increases an animals feed requirements

- generates odour

- increases feed and water trough contamination

- increases soiling/contamination of animals.

Ideally pens should be aligned so the slope is from front to back, ensuring run-off drains out the back of the pen and does not flow into adjacent pens.

Soil type

Medium clay loams are the preferred soil type. These are easily compacted, preventing groundwater contamination and infiltration.

Avoid siting confinement areas on sandy/light soils as these generally have high infiltration rates and therefore a greater groundwater contamination risk and are more prone to erosion by wind, rain and traffic.

Heavy, clay-rich soils tend to ‘pug’ when wet and dry slowly, increasing odour and animal health and welfare problems.

Access

The confinement area needs to be accessible for feed delivery and stock movements in all weather, particularly during wet or inclement weather. The suitability of both the access road from the feed storage and mixing area, as well as the feed delivery area of the pen or small paddock need to be considered. Use of existing compacted roads may be an option or the use of gravel may be required to prevent bogging or excessive dust.

Proximity to facilities

Locating the confinement area close to existing feed storages and machinery sheds can greatly reduce the travel time when feeding and can also reduce access issues during difficult weather. Being close to existing livestock yards reduces the distance sick animals must be moved if treatment is necessary and can make use of existing facilities such as loading ramps, races and cattle crushes.

Distance from the house or other residences on the property also needs to be considered. Close proximity makes monitoring of the stock easier and issues are likely to be picked up quickly. However, the impact of dust, odour, noise, insects and the overall appearance of the confinement feeding area need to be considered.

Access to water

A guaranteed supply of good quality water to the confinement area is essential. Water should be supplied to livestock through troughs as dams will rapidly become contaminated and may become boggy as water levels fall.

Stock access to creeks or waterways should not be permitted.

Shelter

Stock in confinement areas should be sheltered from prevailing winds during winter. Vegetation shelter belts can be planted/located to protect the confinement area from the prevailing winter winds to minimise wind and dust related issues.

Be mindful of air flow during summer to minimise heat stress.

Residues

Care must be taken that confinement feeding areas are not located in areas with old buildings, orchards or other food production areas, power poles, sheep yards or dips that may be contaminated with persistent chemicals, for example arsenic or organochlorines.

Aspect

Confinement feeding areas should have a northerly aspect to maximise solar radiation and evaporation rates. Avoid southerly aspects that remain wet during winter.

Biodiversity and vegetation

Identify native vegetation on the site and options to retain or enhance cover and quality. If possible, avoid clearing these areas. Be aware of potential impacts down slope of nutrient build up and the negative impact this can have on native vegetation, especially trees.

Biosecurity

Before deciding on a confinement area site, consider any potential ‘risk sources’ such as nearby houses, roads, stock or waterbodies. The staff at your Local Land Services office can provide advice to mitigate biosecurity risks.

Confinement feeding areas should be included in your properties biosecurity plan.

Future expansion

Your confinement area site should take in to account the possibility of future expansion. A rough rule of thumb is to have three times the pen area to allow room for laneways, working yards/areas and moving of machinery if needed.

Cultural heritage

Identify Aboriginal cultural heritage values on the site and options to avoid impacts. Local Land Services can provide assistance to landholders. Cultural due diligence must be followed.

Waste disposal

Waste from confinement systems can include spoilt feed, manure, water and carcases. Consider whether:

- solid wastes can be removed, stockpiled or composted and reused on-farm

- water wastes can be controlled and isolated (ponds or dams) and/or reused (irrigation)

- carcases can be deep-buried or composted.

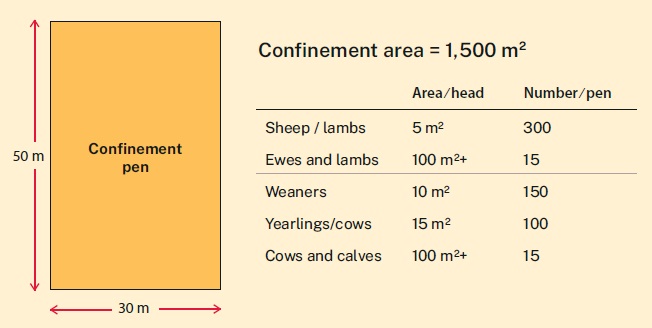

Confinement feeding area stocking densities

Stocking density recommendations within confinement systems vary across states and range from 2-5 m2 per head for sheep and 9-25 m2 per head for cattle.

On a state by state basis there appears to be far greater uniformity and agreement in terms of cattle stocking density recommendations. There has been a lack of definitive research in terms of stocking density impact(s) on social welfare, stress and livestock performance within sheep confinement systems. Lambing/calving within confinement pens is not recommended. Small paddocks are more appropriate.

The following stocking density recommendations can be used as a minimum area per head guide within confinement systems:

- sheep or lambs 5 m²

- weaner cattle 9-10 m²

- yearling cattle 12-14 m²

- dry cows 15-25 m²

- ewes and lambs 100 m²

- cows and calves 100+ m².

Increasing stocking density, that is reducing the area per head, may help to reduce dust within the confinement area. As the number of stock in a given area increases, the quantity of urine and manure deposited on the pen surface increases, therefore adding moisture to the surface and reducing dust.

Increased stocking densities also reduce infrastructure costs, with less pen space/fencing required per animal. However, higher stocking densities can result in an increase in animal health related problems.

Mob sizes

With sheep, mob size is generally dictated by confinement pen area, with most producers basing mob size on numbers able to be held when using a stocking density of 5 m2 per sheep. Smaller mob sizes help with management, feeding and monitoring of the animals and may reduce social stress and shy feeder numbers in young stock (lambs, weaner cattle). Older, mature stock can be run in larger groups without significant stress or negative impacts on production provided there is adequate feed and water trough space per animal.

Rectangular pens may be a better option than square pen designs when running larger mob sizes or using internal pen feed troughing as they allow for longer, unbroken runs of feed troughing.

Rectangular pens may be a better option than square pen designs when running larger mob sizes or using internal pen feed troughing as they allow for longer, unbroken runs of feed troughing.

Ensure there is sufficient room for the feed-out vehicle to comfortably manoeuvre and turn within the pen.

Suggested mob sizes within confinement systems:

- lambs maximum of 350

- ewes, wethers up to 500

- weaner cattle 50-100

- cows, yearling cattle 100-200.

Stock confinement feeding infrastructure

If possible, look to incorporate confinement pens in and around existing infrastructure such as fences, laneways, working yards, sheds, feed storages (hay sheds, silos, silage pits), roads and reticulated water systems to reduce costs. The following SCA infrastructure would support confinement feeding during drought conditions.

Water supply and quantity

Water is the single most essential element. It is critical in terms of meeting all necessary animal care and welfare targets as well as meeting the physiological needs of stock (such as digestion, blood circulation, temperature control and production).

A stock containment or confinement feeding system needs a reliable supply of good quality water capable of meeting daily stock and operational needs. While not all stock will drink at once, it is important that water be available on demand. Check that supply line pipe size (diameter) and water pressure can deliver water when needed.

Flow rates of at least 10-15 litres/head/hour are recommended.

Water troughs

Provision of high quality, cool water is essential. Young stock may need to be trained to recognise and use troughs.

Troughs should be drained and cleaned regularly. Frequency of cleaning will depend on temperature, winds, evaporation, contamination and algae growth. Daily cleaning is recommended during summer, while twice weekly cleaning may be sufficient during the cooler months.

Water trough length will vary according to number of sheep/lambs or cattle per pen, number of water access points, trough design and water pressure.

Water trough space recommendations are:

- Sheep, 30 cm plus 1.5 cm per sheep

Example: 300 sheep

= 30 cm + (300 1.5 cm)

= 30 + 450 cm

= 4.8 m total lineal access

- Cattle, 30 mm/head and/or space for 10% of stock to access water simultaneously during normal weather conditions and 75 mm/head during hot conditions.

Example: 100 cattle

= 30 mm x 100

= 300 mm

= 3 m of linear trough space during normal conditions or 7.5 m during hot conditions.

Water trough options

Troughing can be made using a wide range of materials. Longevity, durability, heating, fouling and cost must be considered when deciding on the material used. Common water trough materials include reinforced concrete, polyethylene, fiberglass, steel and low volume PVC pipes.

Rectangular rather than round troughs are recommended. Rectangular troughs can be comfortably sited within pens or along fence lines, are easily cleaned, provide more linear space (as the same volume round ones) and low-volume systems are available. These low-volume troughs effectively waste less water during cleaning.

If possible, consider having multiple watering points or troughs within your confinement area. Placing troughs within fence lines for example have several advantages including:

- multiple access points reducing stress on lower order or timid animals

- backup if one trough is damaged or unavailable

- greater animal/trough contact as stock ‘walk’ fence lines

- better distribution of manure throughout pens

- traffic or stock pressure spread across several areas.

Estimating water requirements

To meet average daily water requirements budget on providing a minimum of ~10% of the animals liveweight. For example, mature sheep and cattle will need ~5 and between 30-60 litres/day, respectively.

Alternatively, you can budget on stock drinking between 2.5-3 times what they eat. Poor quality water will reduce water intake and animal production.

Feeding systems

Some form of feed bunk or troughing is required in containment areas to separate the feed from the ground. Trail feeding, on the ground is NOT recommended for confinement feeding as the risk of livestock ingesting soil is considerable and the quantity of feed wasted is substantial.

Feed bunks and troughing

Troughing can be made using a wide range of materials. Longevity, durability and cost must be considered when deciding on the material used. When using troughing within your confinement pens, it’s important to consider:

- cost per lineal metre

- durability/expected longevity of the troughing material

- cleaning ease - open ends will facilitate easier cleaning and better drainage

- including drainage holes along the trough length in case of wet weather.

How much space do sheep and cattle need at a trough?

Recommended trough space allocations (once-daily feeding) and specifications are:

Sheep need 350-450 mm wide each.

- double side access 15+ cm/head

- single side access 30+ cm/head

Cattle need 550-600 mm wide each.

- weaners 30 cm/head

- yearlings 40 cm/head

- adult cattle 60 cm/head.

Trough space allocation may be reduced if feeding a grain or pelleted ration out more than once daily and/or alternate feed (hay, silage or straw) is available separately.

Self-feeders

Self-feeders have the advantage of feed being available 24/7 and have a reduced labour requirement, as less time is spent feeding out compared to trough feeding systems. Self-feeders do not generally need to be filled every day and may allow twice a week feeding if their capacity is sufficient.

The constant availability of feed may lead to greater intake, weight gain and feed conversion efficiencies, however, if feeding for maintenance this may not be the required outcome. Self-feeders are relatively expensive; however, less linear feeding space is required per head and they are reasonably robust.

Most sheep-based systems utilise a ‘lick’ mechanism to semi-regulate daily grain and/or pellet intakes. The ‘lick’ mechanism is designed to minimise gorging/overeating of grain or pellets and therefore minimise acidosis risk. Regardless of testimonials and anecdotal evidence, no ‘lick’ style feeder has consistently shown that they can accurately deliver maintenance and/or survival only amounts within confinement feeding systems.

There are a limited number of self-feeders available that can efficiently deliver total mixed rations. The roughage component of total mixed rations restrict their ability to “flow” through self-feeders and can result in the grain and roughage separating or the ration bridging in the feeder and not being available to the stock.

Self-feeders that can handle total mixed rations generally have a large opening or tray at the bottom, making the limiting of feed intake almost impossible. Total mixed rations are more commonly used within cattle confinement systems and bunk style troughing remains the primary feeding system used.

Self-feeders may be used when higher intakes are acceptable, however, troughs are still usually required to start cattle on feed. Self-feeders can make it difficult to change grains or ration mix quickly.

Recommended self-feeder space allocations for rectangular feeders are:

- Sheep: 3-5 cm/head (100-120 head per 2.4 metre feeder).

- Cattle: 7-10 cm/head (50-70 head per 2.4 metre feeder).

Shade and shelter

It is always recommended that shade and/or shelter be readily available within any confinement or open grazing situation. Shade may be provided by existing trees or structures such as sheds within or around confinement pens.

Care must be taken to protect the bark and immediate base of trees from stock. Options include use of barrier fencing, wrapping tree trunks in chicken wire or equivalent and/or use of chemical retardants such as an ammonium sulphate/water mix sprayed on exposed trunk and limbs. Due to high nutrient loads, especially phosphorous, native trees may die in or around confinement pens.

If providing artificial shade structures principles of shade design include:

Size - Provide adequate shade for each animal within the confinement area. Recommendations for sheep/lambs are a minimum of 0.4 m2 per animal and 2 m2/head for cattle.

Location - Ideally shade should be located away from feed and watering points. If shading water troughs, provide additional shade areas to minimise congregating and bullying around water trough areas that can limit water intake for some animals.

Orientation - North-south shade orientation will maximise the amount of shade available throughout the day within each confinement pen and the shade footprint will move across the confinement area allowing the ground surface to dry.

Material - type If using shade cloth, chose one with minimum solar rating of 80%, minimum 300 GSM (gram per square metre) and at least a 10-year warranty against UV degradation. Shade cloth tension must be adequate to prevent damage during windy conditions. Galvanised and/or corrugated iron reflects more solar radiation than shade cloth however they may need additional support due to the weight. Steel posts, set in concrete to prevent corrosion and damage, are recommended.

Height / ventilation - Ensure any shade structure is high enough so as not to interfere with cleaning or drying. Shades should be constructed to maximise ventilation and afternoon shade.

You can download this information and additional advice on stock containment areas, confinement feeding pen design, feed requirements, health and welfare, and budgeting tools in the 2023 LLS A guide to confinement feeding sheep and cattle in NSW PDF, 5591.67 KB